The World's First

AI-based Unmanned RMRF

The world's first

AI-based unmanned RMRF

The world's first

AI-based

unmanned RMRF

At a glance

Innovative Robot-based

sorting solution

High-quality r-PET Flake

Production

Reducing 25t* of

Carbon Footprint

Everyday

* Atron as of the 30s

Innovative Robot-based

sorting solution

High-quality r-PET Flake

Production

Reducing 25t* of

Carbon Footprint

Everyday

* Atron as of the 30s

Innovative Robot-based

sorting solution

High-quality r-PET Flake

Production

Reducing 25t* of

Carbon Footprint

Everyday

* Atron as of the 30s

Innovative Robot-based

sorting solution

High-quality r-PET Flake

Production

Reducing 25t* of

Carbon Footprint

Everyday

* Atron as of the 30s

Limitations of The Hand-based MRF*

Limitations of hand-based MRF

Of the 800,000 tons of PET plastic produced annually, it is estimated that 250,000 tons can be recycled. However, most sorting facilities are unable to handle the workload due to labor shortages and low sorting accuracy. As a result, most plastic is either processed by incineration or disposed of in landfills.

Of the 800,000 tons of PET plastic produced annually, it is estimated that 250,000 tons can be recycled. However, most sorting facilities are unable to handle the workload due to labor shortages and low sorting accuracy. As a result, most plastic is either processed by incineration or disposed of in landfills.

* MRF: Recycling Sorting Facility(Material Recovery Facility)

* MRF: Recycling Sorting Facility(Material Recovery Facility)

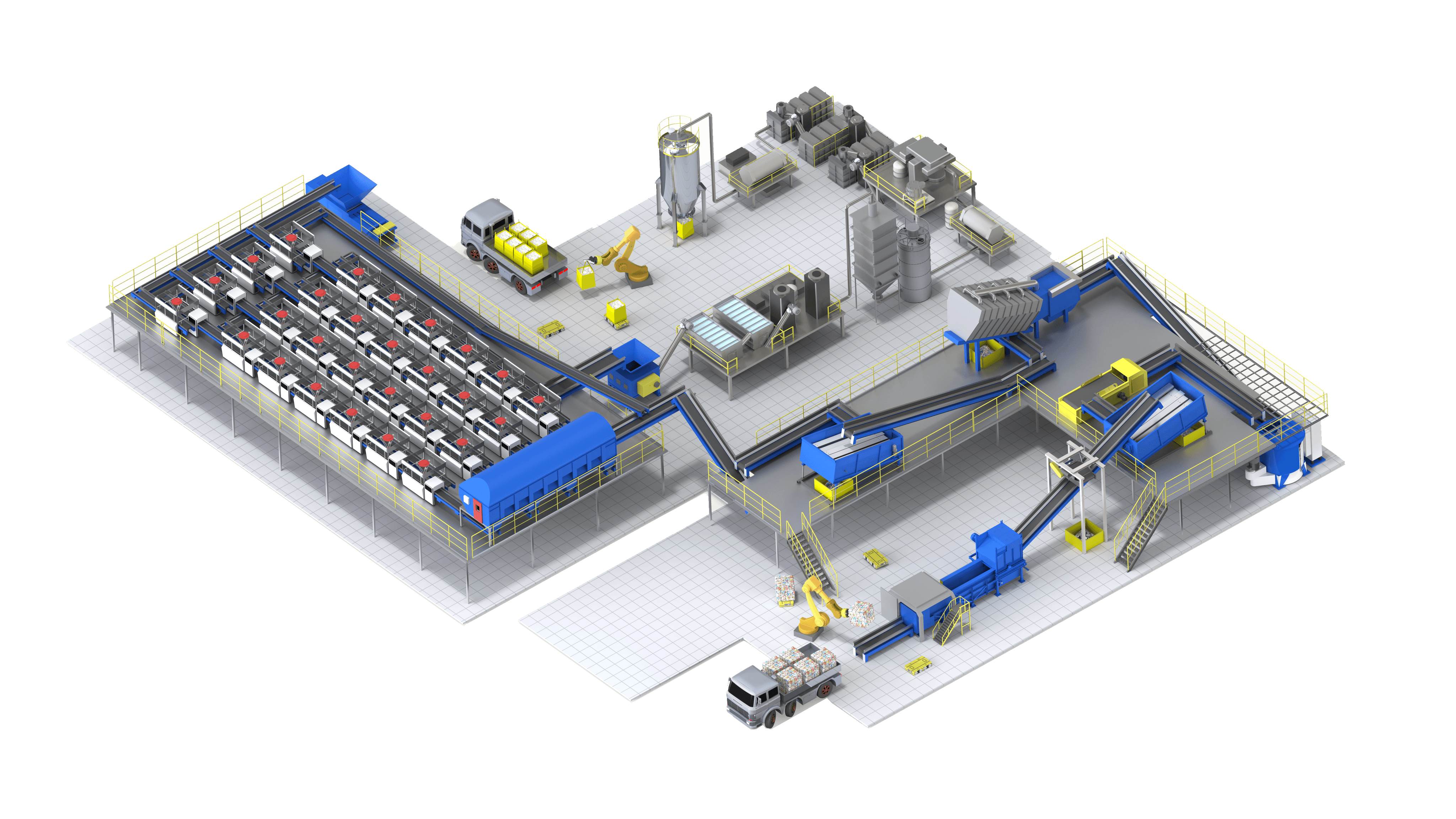

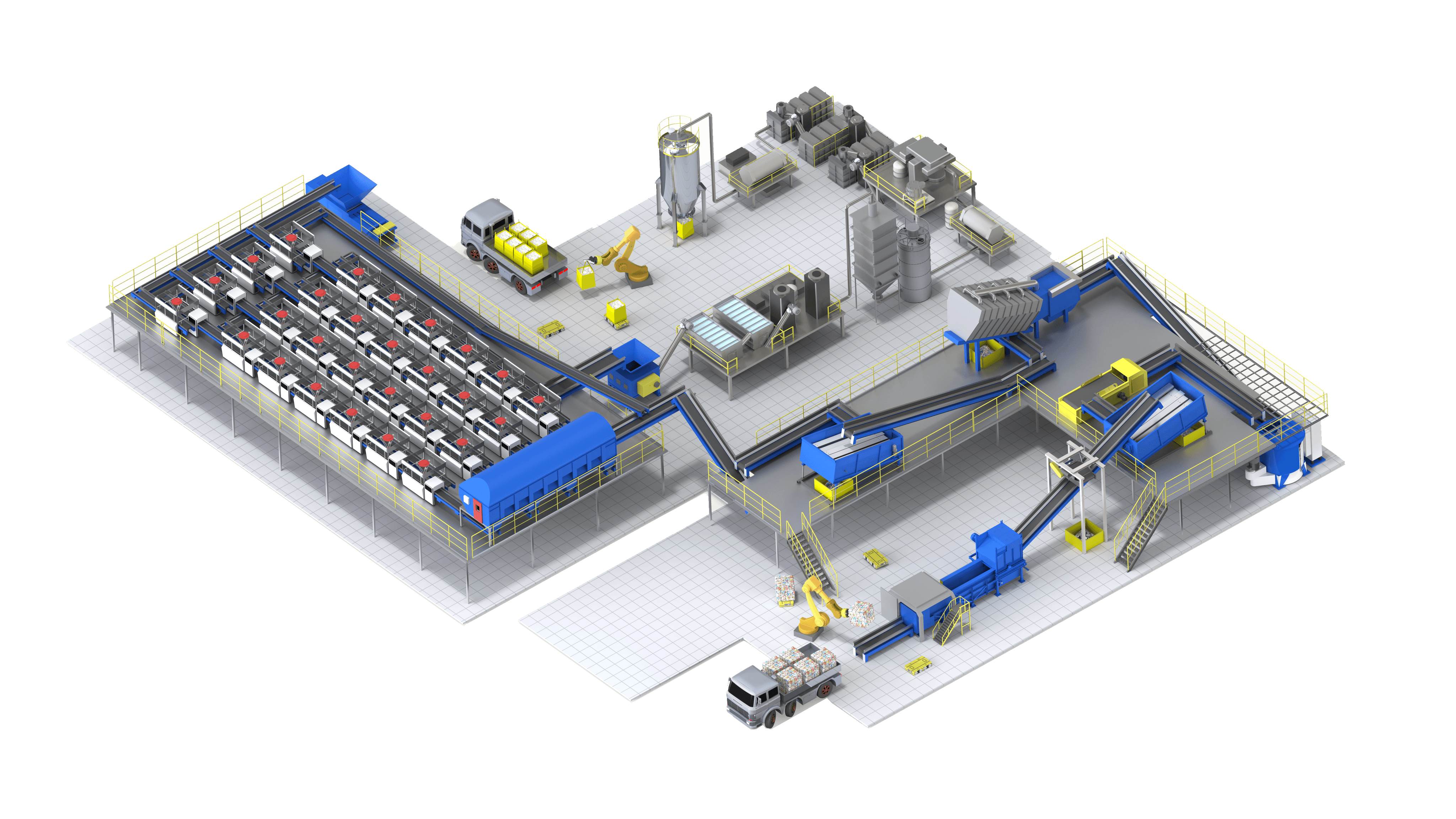

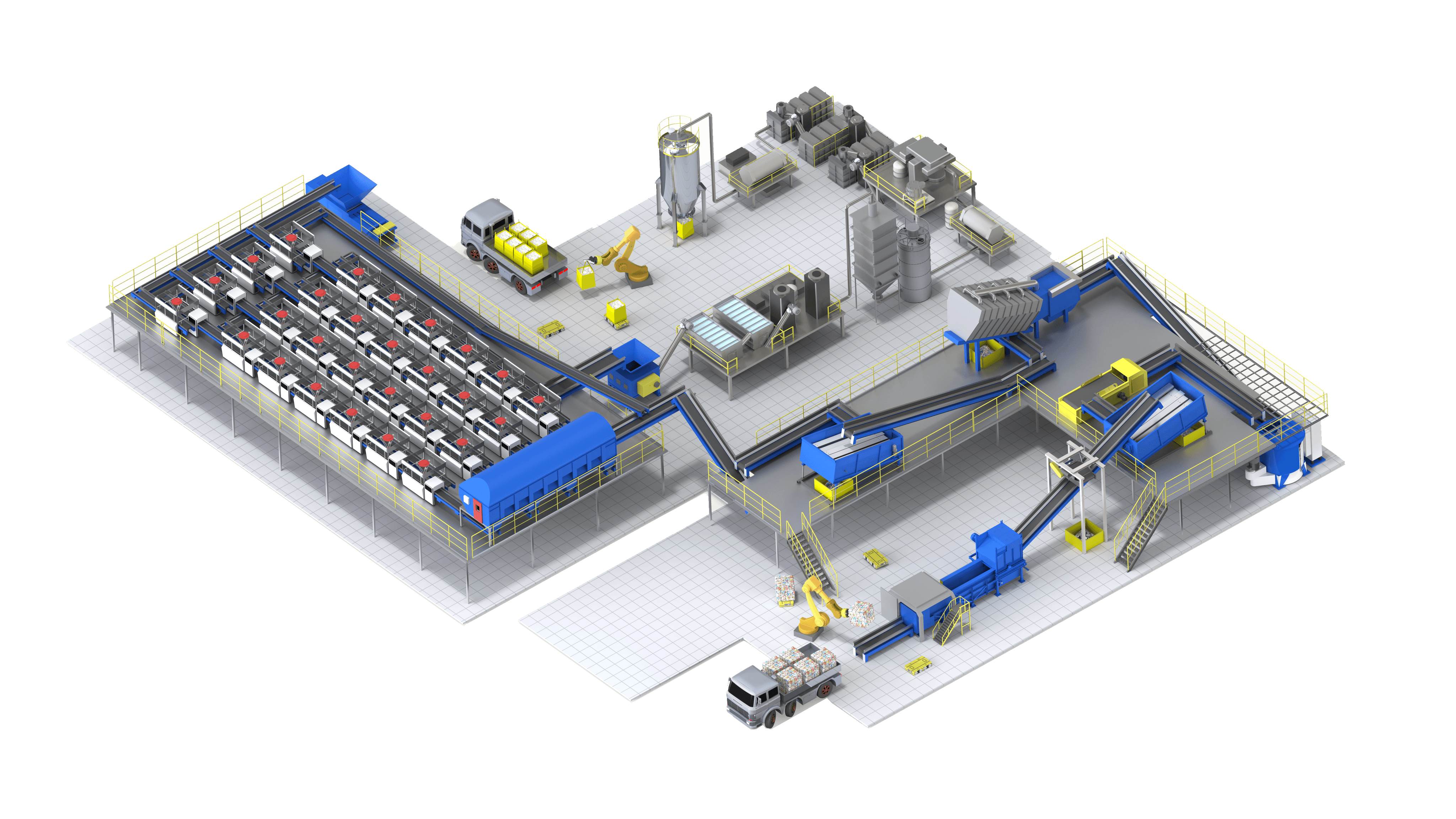

airo-mrf

airo-mrf

AI robot-based unmanned resource sorting center, the world's first, Airo-MRF is AI robot-based unmanned resource sorting center operated by robots including Atron, and aims to overcome the limitations of existing MRFs with AI technology and achieve a 2x increase in resource circulation rate.

AI robot-based unmanned resource sorting center, the world's first, is AI robot-based unmanned resource sorting center operated by robots including Aitron, and aims to overcome the limitations of existing MRFs with AI technology and achieve a 2x increase in resource circulation rate.

AI Robot-based Unmanned MRF

With Innovative Sortation Technology

Innovative selection technology embedded

AI robot-based MRF

Innovative sorting technology embedded

AI robot-based MRF

Sorting solution composed of more than 10 Atrons

Sorting solution composed of more than 10 Aetrons

Atron has an object recognition accuracy of 99%, with a maximum of 96 sortation per minute.

And based on this, it shows the following effects compared to other secondary selectors.

Atron has an object recognition accuracy of 99%, with a maximum of 96 sortation per minute and based on this, it shows the following effects compared to other secondary selectors.

Reduced sorting costs

Reduced sorting costs

279%

279%

Increase in working hours

Increase in working hours

126%

126%

Increase sorting speed

Increase sorting speed

240%

240%

The Airo-MRF is composed of a minimum of 10 Atrons, offering a revolutionary separation throughput and high separation accuracy compared to conventional MRFs, making it possible to produce high-purity recycled plastic raw materials.

airo-mrf is composed of a minimum of 10 Atrons, offering a revolutionary sortation throughput and high separation accuracy compared to conventional MRFs, making it possible to produce high-purity recycled plastic raw materials.

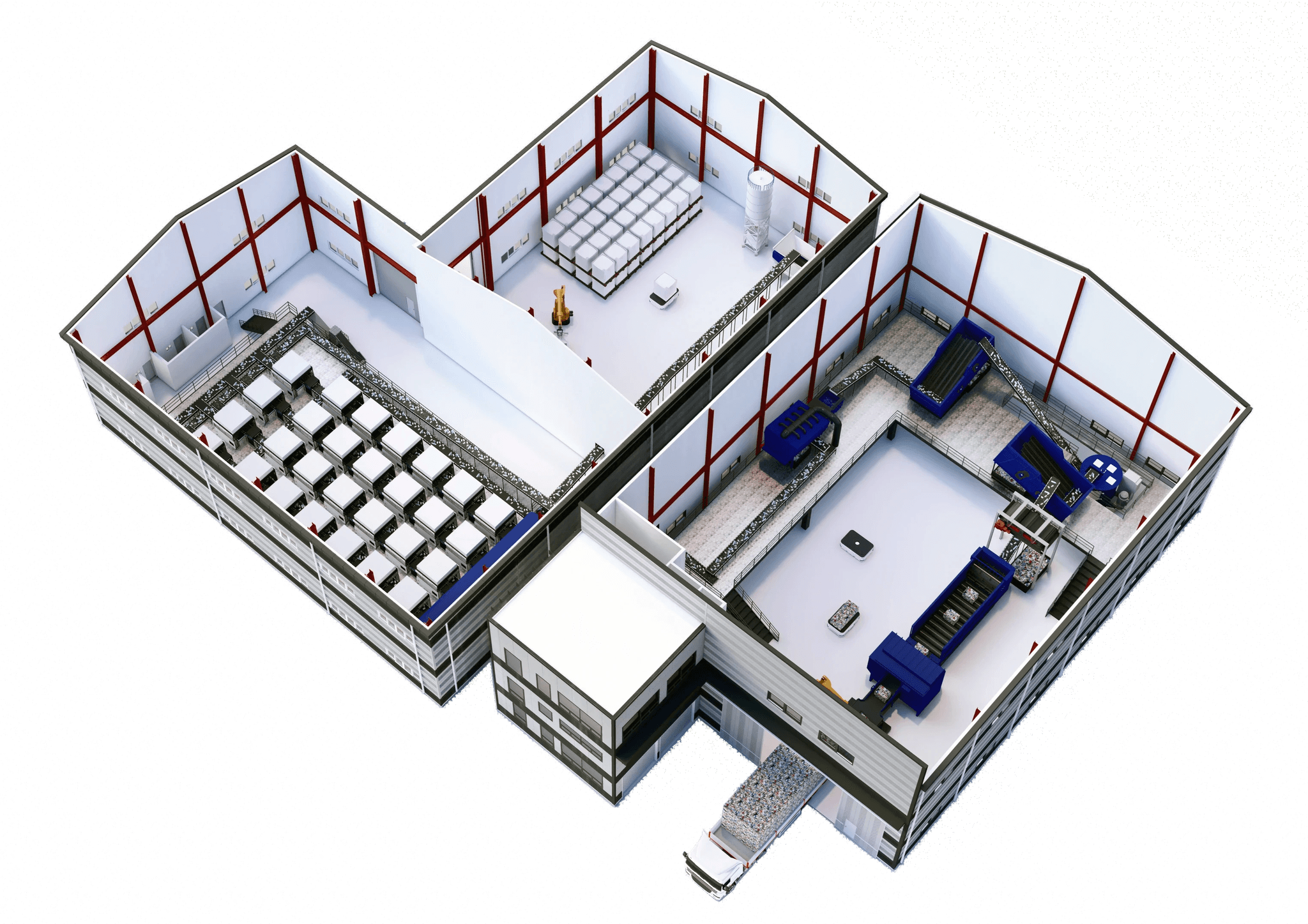

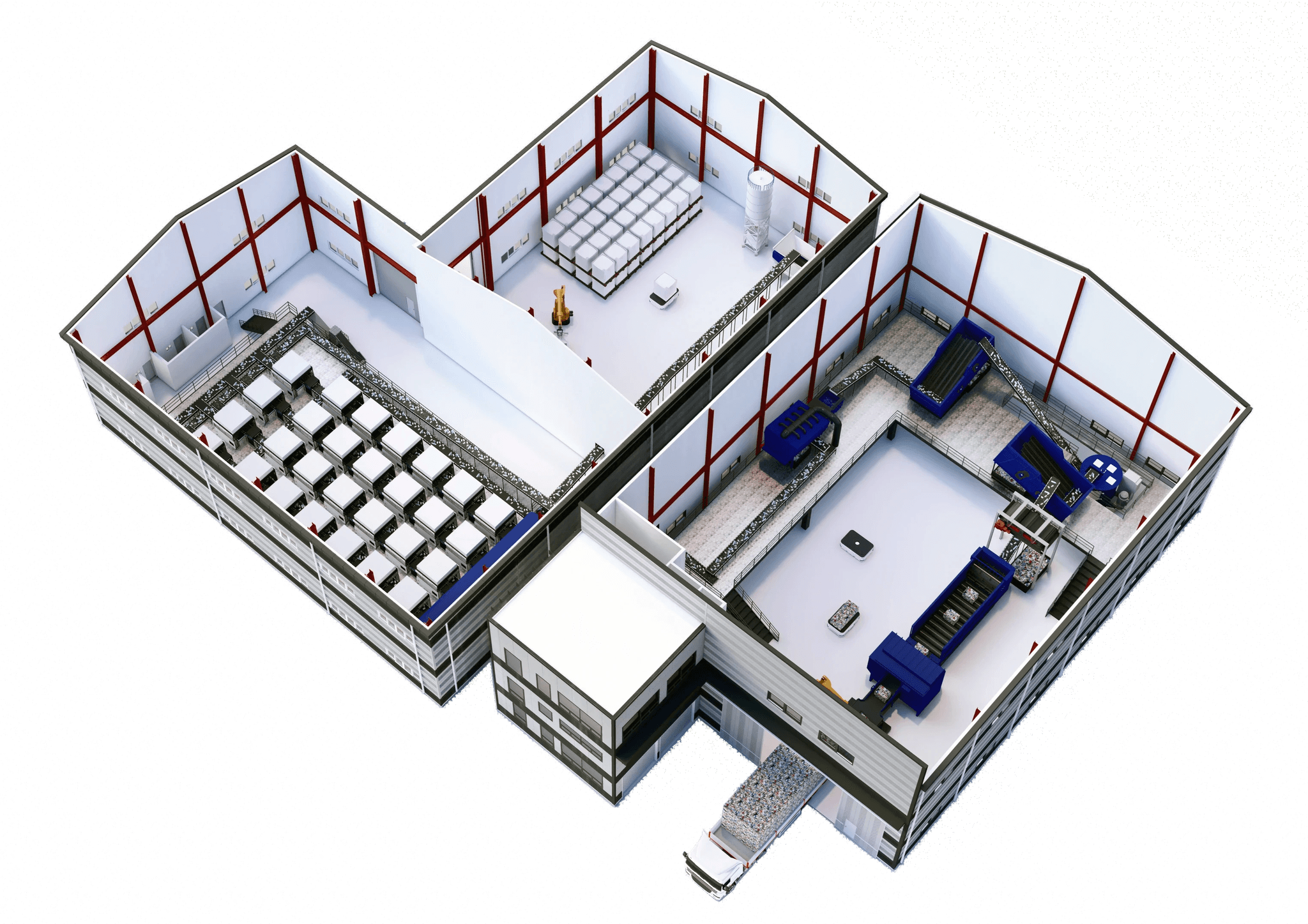

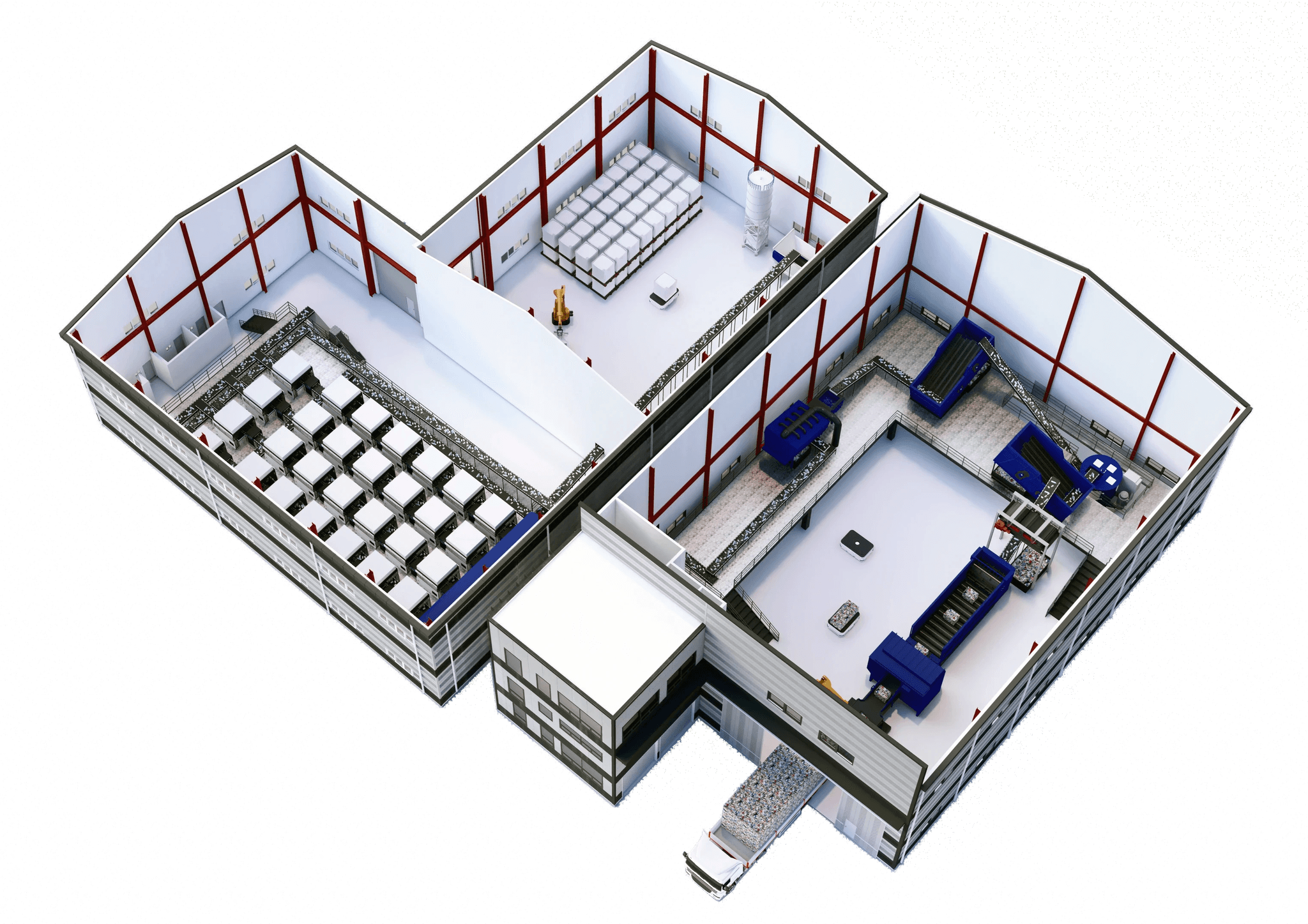

Everything Is Unmanned

Everything Is Unmanned

Airo-MRF is unmanned from circular conveyor belts to loading and unloading robots, wind power sorters, and magnetic sorters. Labor shortage due to aging and lack of labor can be resolved, and work safety issues can be addressed, allowing increased processing capacity compared to manual sorting.

airo-mrf is unmanned from circular conveyor belts to loading and unloading robots, wind power sorters, and magnetic sorters. Labor shortage due to aging and lack of labor can be resolved, and work safety issues can be addressed, allowing increased processing capacity compared to manual sorting.

AGV (mobile robot) carrying compressed waste and ton bags

AGV (mobile robot) carrying compressed waste and ton bags

Magnetic separator that separates iron scraps using magnetism

Magnetic separator that separates iron scraps using magnetism

Using wind to sort paper, plastic, etc. by weight, wind sorting machine

Using wind to sort paper, plastic, etc. by weight, wind sorting machine

Bali Stick Sorter to Measure and Classify Waste with Bali Stick Paddles

Bali Stick Sorter to Measure and Classify Waste with Bali Stick Paddles

High-quality of r-PET Production Possible

High-quality r-PET production possible

The importance of recycled materials is increasing. In foreign countries, the mandatory minimum recycled material content for all plastics is 30%, while in domestic cases, the system for marking the use of recycled plastic materials has been implemented since March 29, 24.

The importance of recycled materials is increasing. In foreign countries, the mandatory minimum recycled material content for all plastics is 30%, while in domestic cases, the system for marking the use of recycled plastic materials has been implemented since March 29, 24.

However, quality of recycled materials is as important as production. Currently, many companies are focusing only on production. In that case, it can cause a decrease in the quality of products based on recycled materials, and eventually lead to reliability issues with recycled materials.

However, quality of recycled materials is as important as production. Currently, many companies are focusing only on production. In that case, it can cause a decrease in the quality of products based on recycled materials, and eventually lead to reliability issues with recycled materials.

Innovative sortation process based on Atron reduces multi-stage sortation process to a single step, enabling classification of high-purity materials. Additionally, it efficiently produces high-quality r-PET flakes through automated processes and contributes to resource circulation by selling to required recycling facilities.

Innovative sortation process based on Atron reduces multi-stage sortation process to a single step, enabling classification of high-purity materials. Additionally, it efficiently produces high-quality r-PET flakes through automated processes and contributes to resource circulation by selling to required recycling facilities.

Expectation

Expectation

2X of Recycling Rate

2X of Recycling Rate

2X of Recycling Rate

Landfill / Incineration ↓

Landfill / Incineration ↓

Recycling Rate: 70%

Recycling Rate: 70%

Recycling Rate: 70%

Carbon footprint reduction

Carbon footprint reduction

Carbon footprint reduction

with 30 Atrons

with 30 Atrons

25t / Everyday

25t / Everyday

25t / Everyday

with 30 Atrons

World's First Robot Resource Recovery Center

World's First

Robot Resource Recovery Center

World's First

Robot-based Resource Recovery Center

Flagship Center, scheduled to open in 2025 (Specialized complex for resource circulation in Seo-gu, Incheon)

Flagship Center, scheduled to open in 2025 (Specialized complex for resource circulation in Seo-gu, Incheon)

Flagship Center, scheduled to open in 2025 (Specialized complex for resource circulation in Seo-gu, Incheon)

Aetech Co., Ltd

help@aetech.co.kr | +82-2-838-6034 | HQ_PT-G03, Green Cluster, Jungseojin-ro 410, Seo-gu, Incheon | Seoul Branch_13, Digital-ro 27-gil, Guro-gu, Seoul | Robot Resource Recycling Center_3, Guemsan-ro, Seo-gu, Incheon (Gyeongseo Eco-Recycling Center)

Aetech Co., Ltd

help@aetech.co.kr | +82-2-838-6034 | HQ_PT-G03, Green Cluster, Jungseojin-ro 410, Seo-gu, Incheon | Seoul Branch_13, Digital-ro 27-gil, Guro-gu, Seoul | Robot Resource Recycling Center_3, Guemsan-ro, Seo-gu, Incheon (Gyeongseo Eco-Recycling Center)

Aetech Co., Ltd

help@aetech.co.kr | +82-2-838-6034 | HQ_PT-G03, Green Cluster, Jungseojin-ro 410, Seo-gu, Incheon | Seoul Branch_13, Digital-ro 27-gil, Guro-gu, Seoul | Robot Resource Recycling Center_3, Guemsan-ro, Seo-gu, Incheon (Gyeongseo Eco-Recycling Center)