3nity

The Trinity of

AI x Robot x HW Design

The Trinity of AI x Robot x HW Design

The Trinity

AI

x

Robot

x

HW Design

The Convergence of Three Key Technologies

Smooth integration of the three core technologies

Convergence of Three Key Technologies

3nity(3 core technologies + triNITY) is an AI Powered Robot Control technology that leads smooth integration of AI, robot, and HW design, the core technology of AI sortation robot.

3nity(3 core technologies + triNITY) is an AI Powered Robot Control technology that leads smooth integration of AI, robot, and HW design, the core technology of AI sorting robot.

3nity(3 core technologies + triNITY) is an AI Powered Robot Control technology that leads smooth integration of AI, robot, and HW design, the core technology of AI sorting robot.

AI

AI

Role: Deep learning-based waste location detection and classification, plastic component analysis, object tracking on conveyor, waste statistical data analysis

Role: Deep learning-based waste location detection and classification, plastic component analysis, object tracking on conveyor, waste statistical data analysis“

Artificial intelligence-based solution for real-time detection and classification of waste objects' locations without disrupting the logistics flow at recycling sorting facilities. Independently developed. Forming artificial intelligence learning data based on analyzed results and securing waste big data.

Artificial intelligence-based solution for real-time detection and classification of waste objects' locations without disrupting the logistics flow at recycling sorting facilities. Independently developed. Forming artificial intelligence learning data based on analyzed results and securing waste big data.

Robot control

Robot control

Role: Adaptive robot control for waste shape and situation, robot motion development to maximize waste processing capacity, conveyor and facility control

Role: Adaptive robot control for waste shape and situation, robot motion development to maximize waste processing capacity, conveyor and facility control

Development of control HW/SW to automatically sort waste based on the results analyzed by artificial intelligence. Utilization of robot motion and path to maximize the waste treatment capacity of facilities. Development of emergency stop function for facility status monitoring and accident prevention.

Development of control HW/SW to automatically sort waste based on the results analyzed by artificial intelligence. Utilization of robot motion and path to maximize the waste treatment capacity of facilities. Development of emergency stop function for facility status monitoring and accident prevention.

HW Design

HW Design

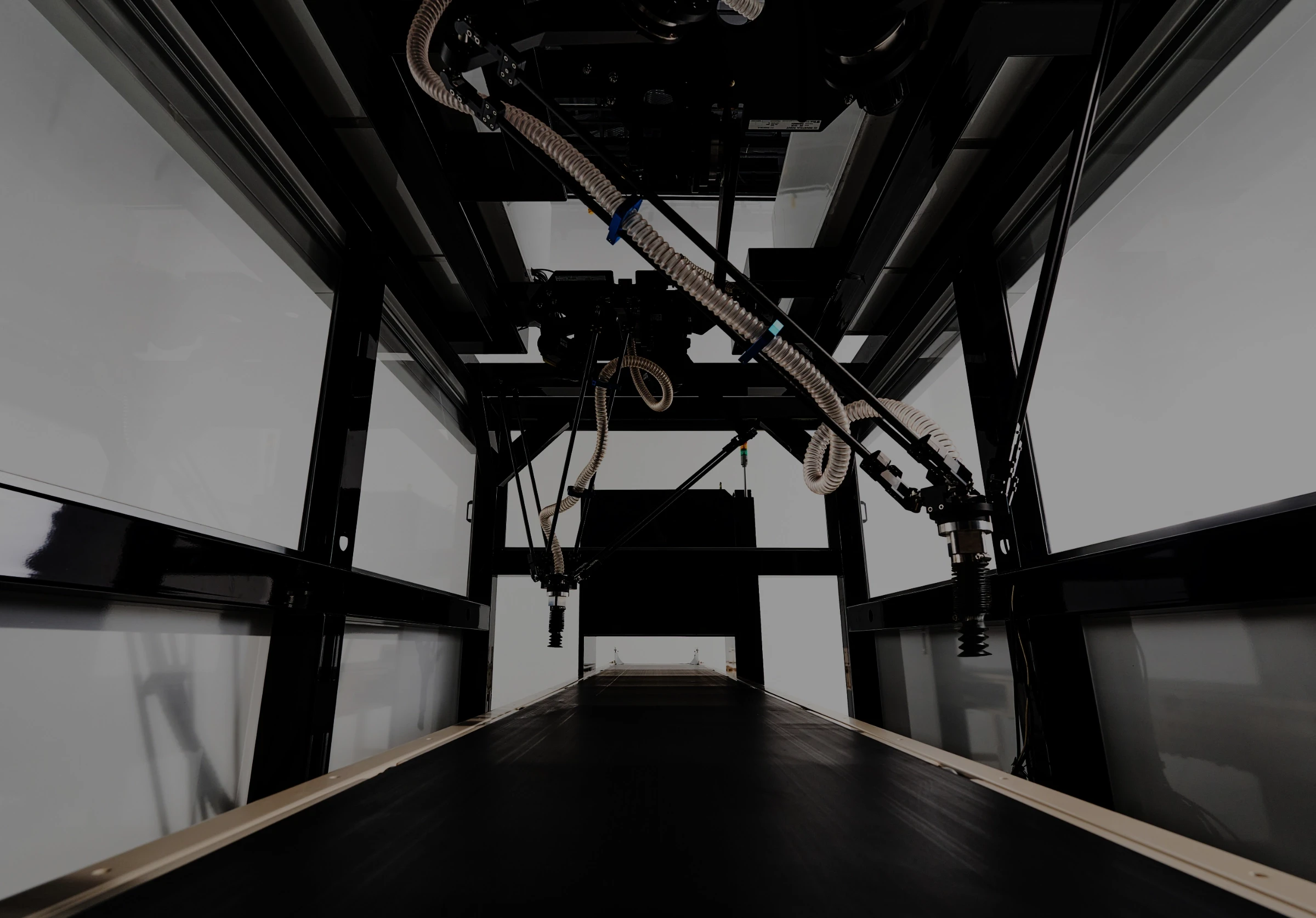

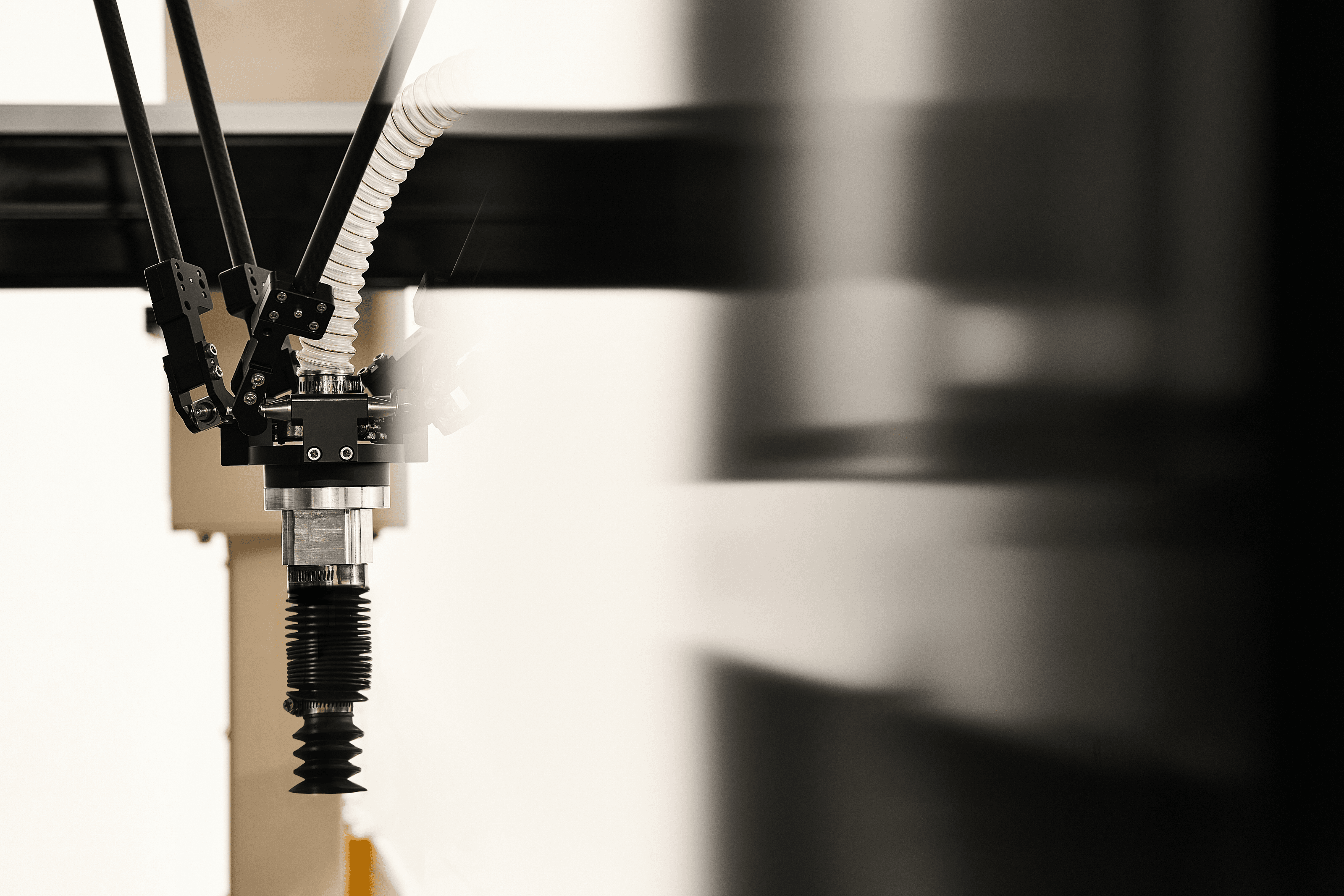

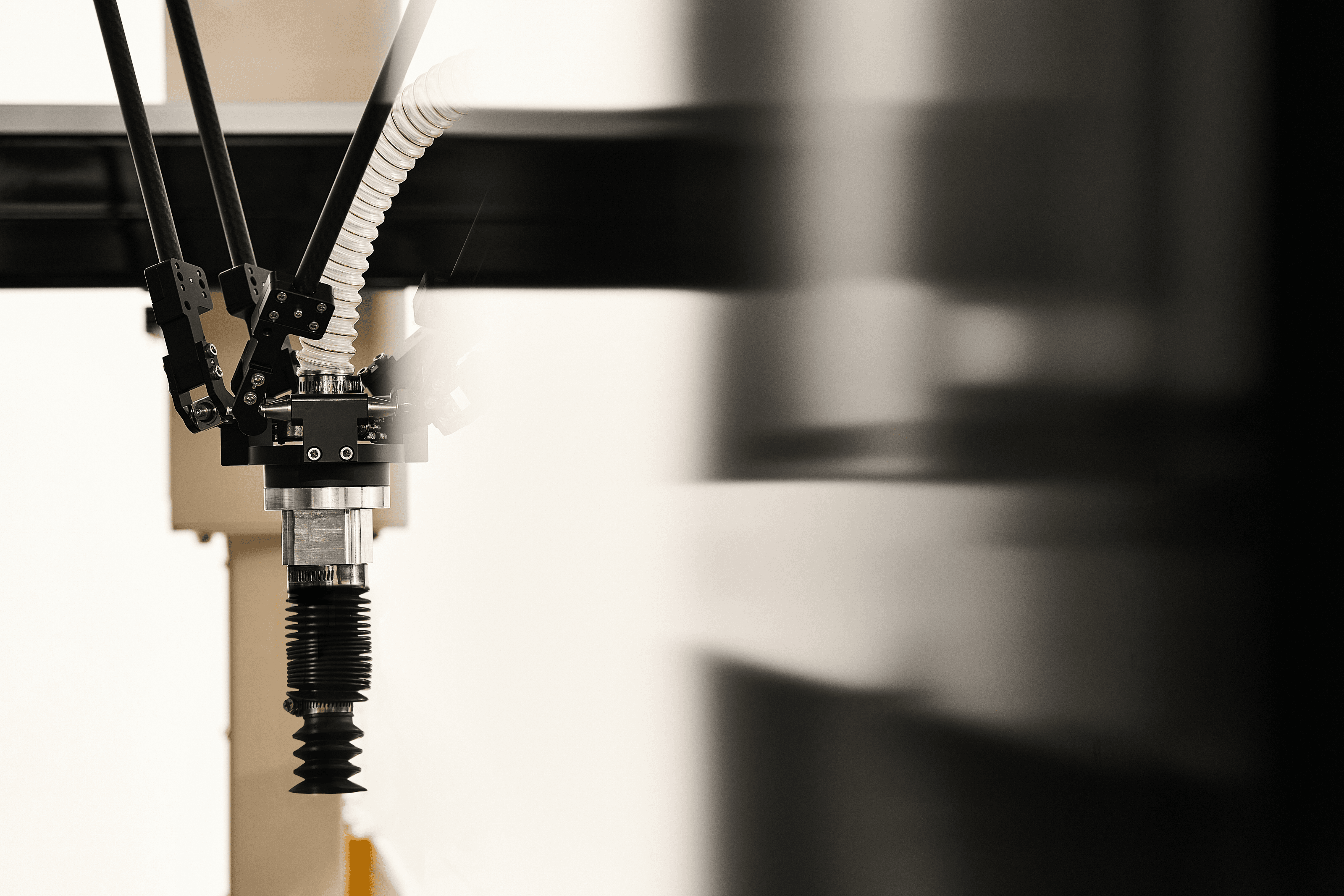

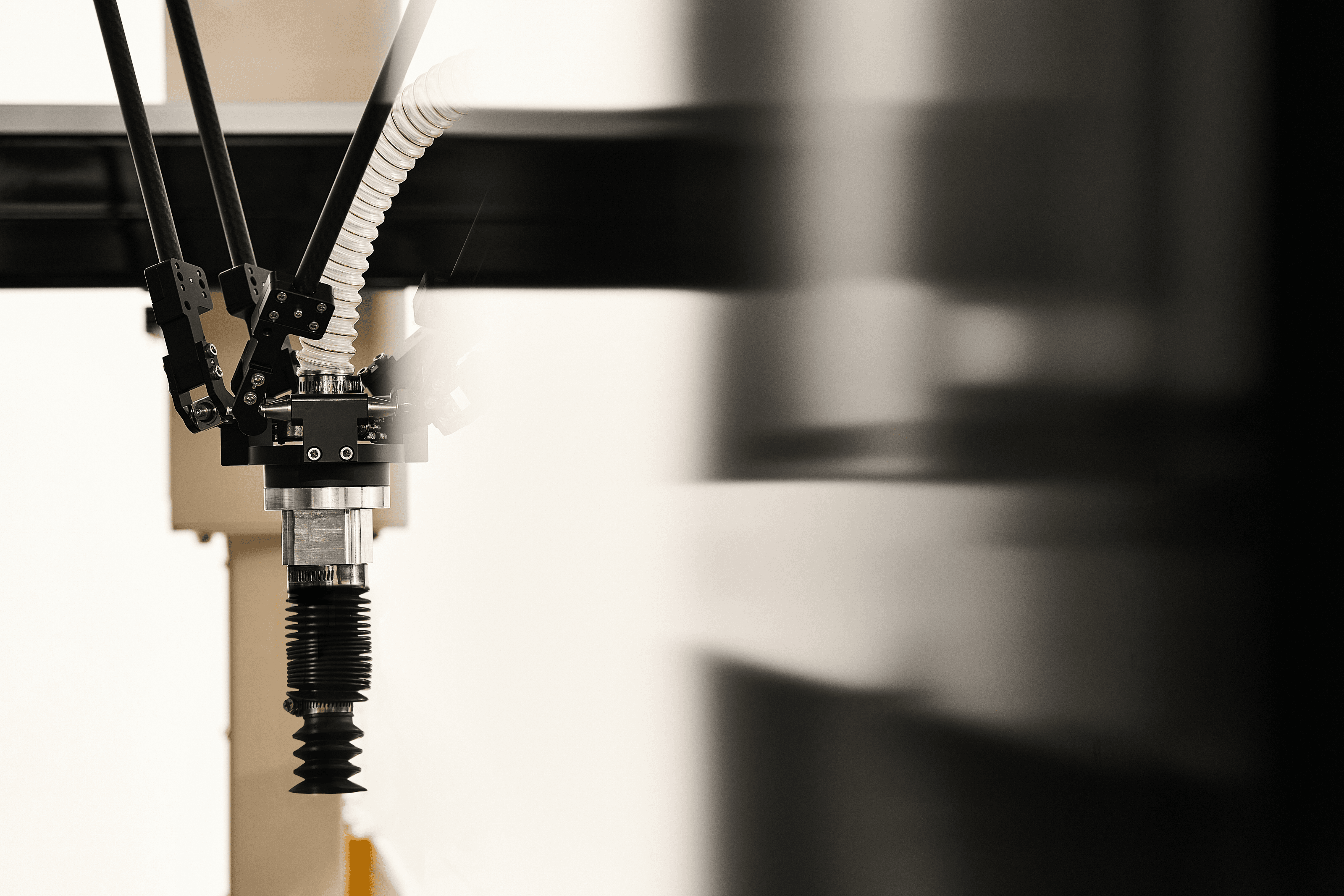

Role: Realizing AI and robots to operate in the real world. HW development and production for each component of A-tron. Deriving solutions to install A-tron in actual field.

Role: Realizing AI and robots to operate in the real world. HW development and production for each component of A-tron. Deriving solutions to install A-tron in actual field.

Design and manufacture of frames for installing Vision optics and Robots. Development of Robot EndEffector for optimizing the success rate of waste Pick&Place. Development of high-speed air direction switching device. Progress of secondary facility construction and electrical work for equipment installation.

Design and manufacture of frames for installing Vision optics and Robots. Development of Robot EndEffector for optimizing the success rate of waste Pick&Place. Development of high-speed air direction switching device. Progress of secondary facility construction and electrical work for equipment installation.

3nity 1.0

3nity 1.0

available soon

available soon

"To maintain a continuous flow, easy maintenance is necessary. You must not stop. To do so, you need the ability to make appropriate judgments and actions for waste objects along with strong durability. For example, the ability to measure the height of waste by yourself to avoid collisions and to grip with appropriate force for each object. To do this, you must not be good at only one thing. An integrated perspective of three technologies (AI, robot control, HW design) is needed."

For continuous maintenance of throughput, easy maintenance is necessary. Don't stop. To do that, the ability to make appropriate judgments and actions for waste objects is required along with strong durability.

For example, the ability to measure waste height by itself to avoid collisions, and to apply appropriate force to each object.

For this, you cannot do well in just one thing. A comprehensive perspective of three technologies (AI, robot control, HW design) is required.

Dogyeong Lee, CTO

Dogyeong Lee, CTO

Upcoming Release Content

Upcoming Release Content

Upcoming Release Content

Waste avoidance capability: precise waste height measurement possible → fewer collisions with waste

Waste avoidance capability: precise waste height measurement possible → fewer collisions with waste

Waste custom adsorption capacity: the ability to adsorb with appropriate force according to the characteristics of each waste

Waste custom adsorption capacity: the ability to adsorb with appropriate force according to the characteristics of each waste

Anticipated Effect

Anticipated Effect

Anticipated Effect

Enhancing robot control ability to increase robot durability

→ Increased maintainability → Maintaining waste sorting capacity

Enhancing robot control ability to increase robot durability

→ Increased maintainability → Maintaining waste sorting capacity

Game Changer of AI-based Robot Solutions

Game Changer of AI Robot Solutions

Aetech's AI robot solution through 3nity resolves problems and enhances capabilities. At the same time, it's a game changer enabling easy maintenance.

Aetech's AI robot solution through 3nity resolves problems and enhances capabilities. At the same time, it's a game changer enabling easy maintenance.

Aetech Co., Ltd

help@aetech.co.kr | +82-2-838-6034 | HQ_PT-G03, 1F, Green Cluster, Jungseojin-ro 410, Seo-gu, Incheon | Seoul Branch_13, Digital-ro 27-gil, Guro-gu, Seoul | Robot Resource Recycling Center_3, Guemsan-ro, Seo-gu, Incheon (Gyeongseo Eco-Recycling Center)

Aetech Co., Ltd

help@aetech.co.kr | +82-2-838-6034 | HQ_PT-G03, 1F, Green Cluster, Jungseojin-ro 410, Seo-gu, Incheon | Seoul Branch_13, Digital-ro 27-gil, Guro-gu, Seoul | Robot Resource Recycling Center_3, Guemsan-ro, Seo-gu, Incheon (Gyeongseo Eco-Recycling Center)

Aetech Co., Ltd

help@aetech.co.kr | +82-2-838-6034 | HQ_PT-G03, 1F, Green Cluster, Jungseojin-ro 410, Seo-gu, Incheon | Seoul Branch_13, Digital-ro 27-gil, Guro-gu, Seoul | Robot Resource Recycling Center_3, Guemsan-ro, Seo-gu, Incheon (Gyeongseo Eco-Recycling Center)